SOLIDWORKS Plastics:Insert molding

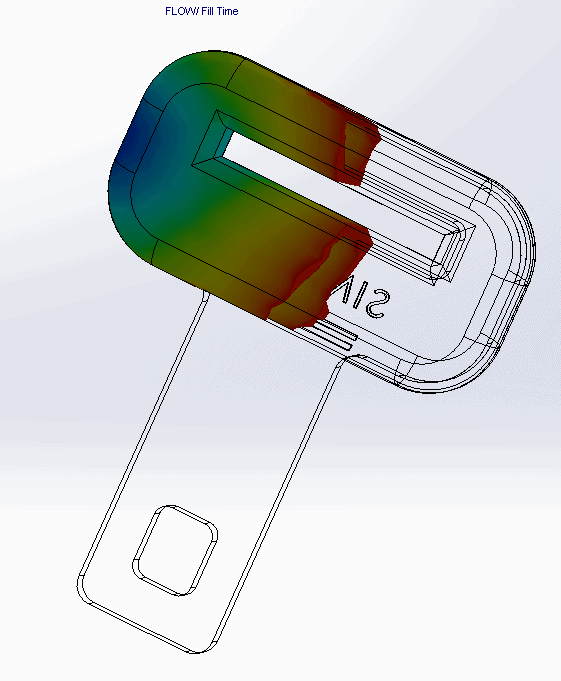

SOLIDWORKS Plastics brings easy-to-use injection molding simulation directly to the designers of plastic parts and injection molds, as well as advanced CAE analysis. It simulates how melted plastic flows during the injection molding process to predict manufacturing-related defects on parts and molds. You can quickly evaluate manufacturability while you design, to eliminate costly mold rework, improve part quality, and accelerate time to market. A Results Adviser provides troubleshooting steps and practical design advice to help diagnose and avoid potential problems.

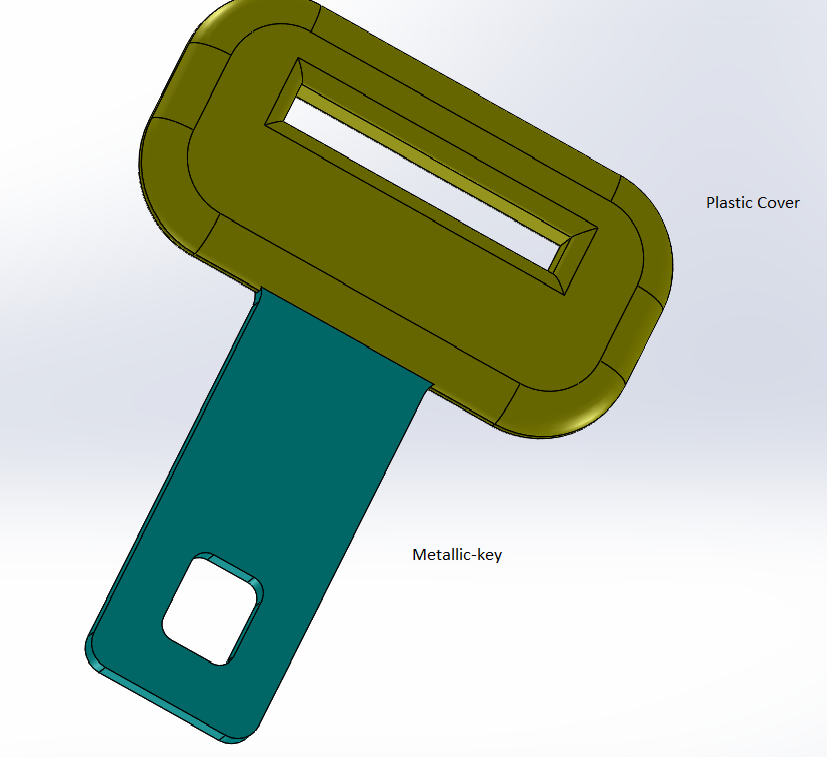

Lets consider a cavity and insert scenario, similar to the keys we carry around everyday. The metallic insert (key) is incased in plastic and we are trying to figure out what does it take to produce thisi configuration using injection molding process. Come to think of it there are many such examples in our day to day lives. eg knives, remote controls, toys etc.

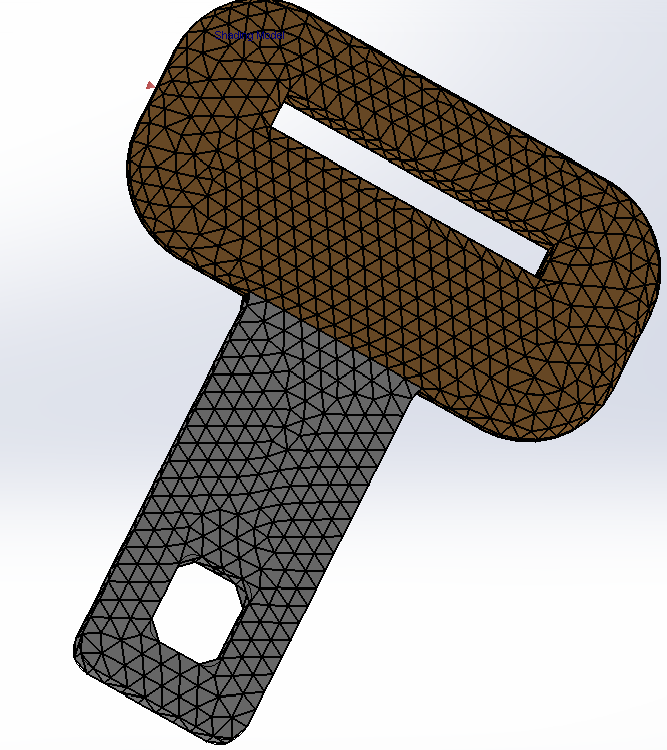

This is a two part model with the yellow being plastic and blue part is metal. In SOLIDWORKS Plastics I can identify the 2 parts separately during mesh and define them as cavity and insert. SOLIDWORKS Plastics generates tetrahedral mesh to capture geometry.

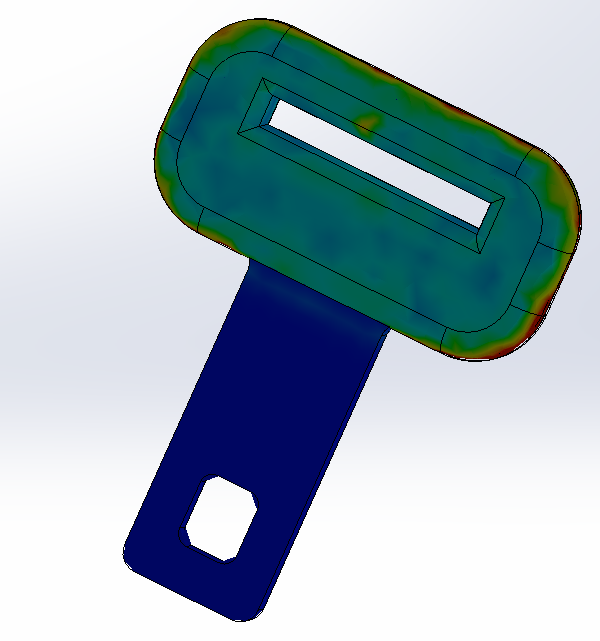

Pack tool calculate what happens in the cavity during pack stage of injection molding process. Residual stress calculated during Pack analysis is a key indicator of warpage. When doing what-if analysis to figure out ideal thickness, material and process parameters etc, it is critical to make sure the residual stresses are going down to ensure design improvement. Residual stress is the stress left in the material due to injection molding process.

Rajat Trehan

Product Manager

Blog

Blog