In-house vs. Outsource - 6 Advantages of Owning a 3D Printer

The benefits of 3D printing and rapid prototyping are numerous and well recognized. Whether it’s design validation,functional testing or faster launch of new products, executives seldom need to be to be convinced of the benefits. Still, many businesses continue to outsource 3D printing because they believe ownership is cost prohibitive.

What many companies don’t realize is that 3D printing has advanced dramatically; the availability of a new breed of high-quality 3D printers at affordable prices now discredits the argument that they are too costly. What’s more, the lower upfront costs of 3D printers represents just the tip of the tangible benefits: Even with relatively few modeling builds, having in-house 3D printing capabilities provides a range of operational and business benefits that provide real bottom-line advantages. The six key advantages an in-house 3D printer offers discussed in this white paper are lower costs; accelerated time to market; competitive advantage; fewer manufacturing errors; greater confidentiality; and improved model accuracy and quality.

Top 6 Reasons to Bring 3D Printing In-House:

1. Lower Costs

An outsourced prototype can cost from several hundred dollars for a simple design to thousands of dollars for a more complex model – as much as three to five times that of a part printed in-house.

Creating the same prototype on an in-house 3D printer brings a significant cost saving, even if your company prints only two models per month on average.

2. Accelerated Time To Market

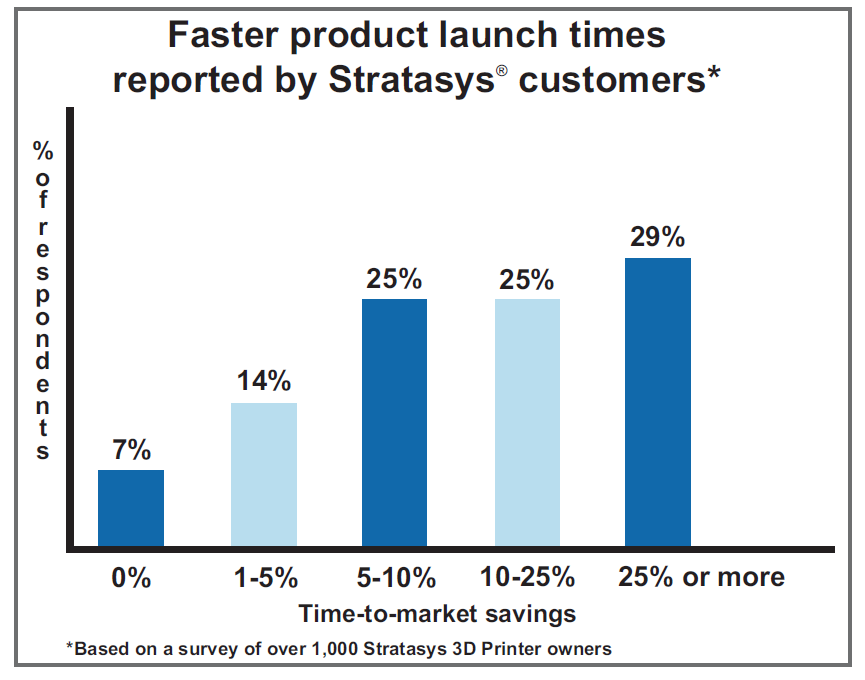

Turnaround time with outsourcing rarely takes the perceived two to three days to get models back. In fact, it normally takes around a week or longer. An in-house 3D printer produces a prototype within hours, rather than days. Additional time can be saved by printing during the night or over the weekend. This can shave weeks off the development cycle and dramatically accelerate time to market for new products and new features for existing products.

3. Frequent Prototyping = Competitive Advantage

Many factors can slow down the introduction of new products during the product development lifecycle – everything from choice of tools to time spent waiting for prototypes to arrive from an outsource vendor. Sidestep this problem with an in-house 3D printing system: Early-stage and frequent prototyping leads to more effective product launches, enabling a company to introduce new innovations to market ahead f their competitors.

4. Fewer Manufacturing Errors

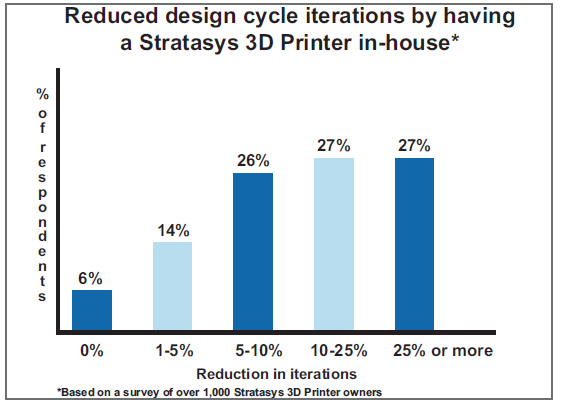

Prototyping reduces manufacturing costs by fine-tuning designs before molds and die casts are made.

When prototyping is readily available and can be done inexpensively in multiple iterations, the potential for design errors is significantly reduced. Designers can test out different ideas to find the optimal design, using small variations on the model to check for functionality.

5. Greater Confidentiality

In today’s competitive market, a leaked design may spell disaster, making it imperative to ensure confidentiality. Keeping rapid prototyping in-house with a 3D printer eliminates the need to transmit design files to any external network. It ensures that designs never leave the company premises, safeguarding intellectual property.

6. Improved Model Accuracy and Quality

Regardless of how a prototype is produced, the goal is to accurately simulate the real-life product. In every field, high-quality, precise models are vital for form, fit and function testing. Quality 3D printers provide functional and visual accuracy. They can print the smallest features and finest details, smooth surfaces, and even moving parts, in a single build. And, with a choice of model materials and varied post-processing options, it is possible to create models that closely resemble the end product.

Having in-house, quality 3D printing capabilities offers significant benefits for the entire product development cycle. Return on investment with an in-house 3D printer is typically fast, even when outsourced modeling is low-volume. The short-term economic return becomes long-term advantage through enhanced innovation, increased confidentiality, more productive design cycles, higher-quality designs and faster time to market.

Information in this article appears in the whitepaper In-house or Outsource: Six Business Advantages of Owning an In-House 3D Printer. Click here to download the original paper.

Jim TeDesco

Marketing Manager

Computer Aided Technology, Inc.

Blog

Blog