I different twist on assembly patterns

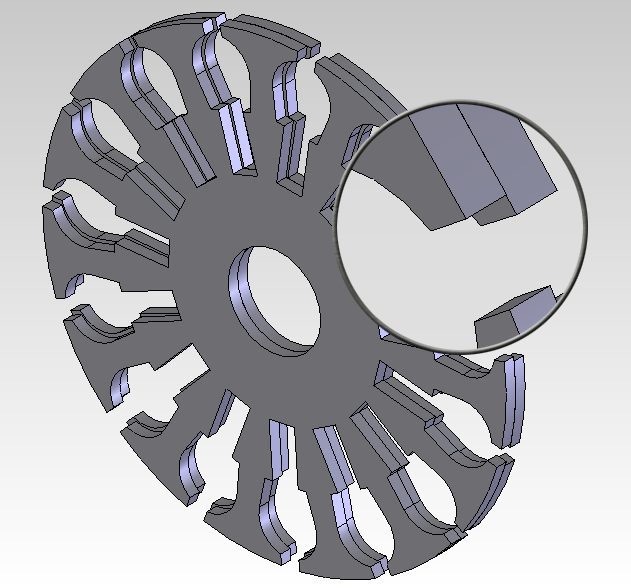

Working with a customer this morning I came up with a nice redneck workaround. This is what the customer as for.

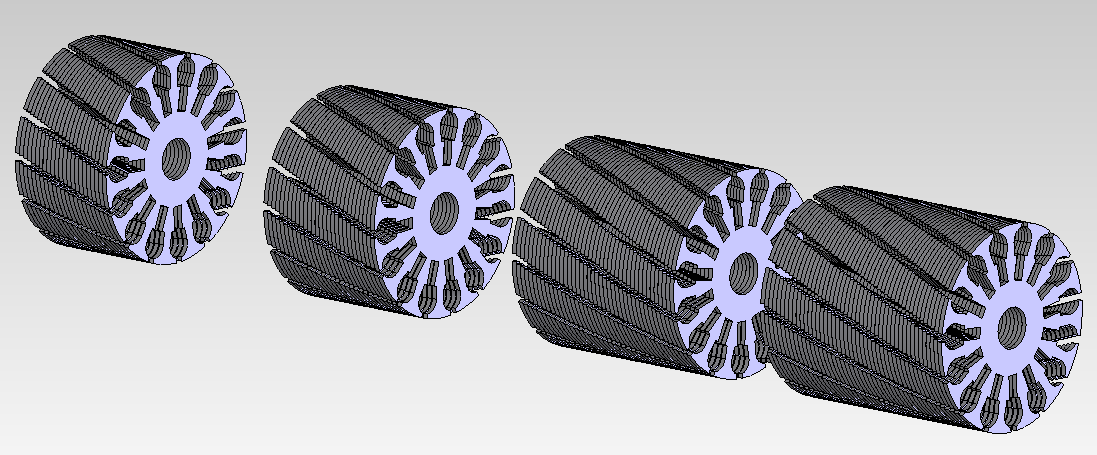

- An assembly comprised of a series of shims stacked up on top of each other.

- Number of shims may vary

- The thickness of the shim stays constant ( but it doesn't matter the process works either way.

- Few mates as possible.

- Hang UP! The stack up turns 1 degree each shim that stacks up. Linear Component pattern won't work.

Here is my Solution. Leverage a Feature Driven Pattern.

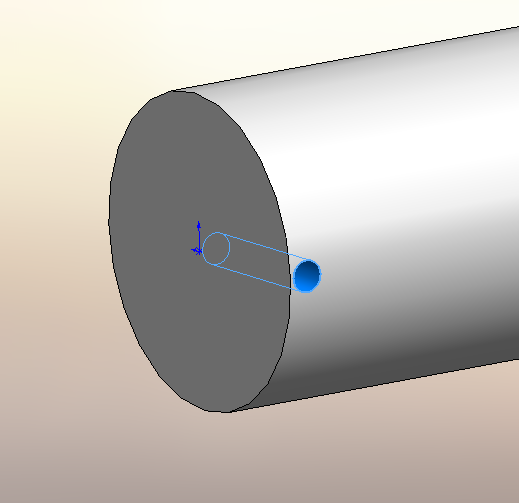

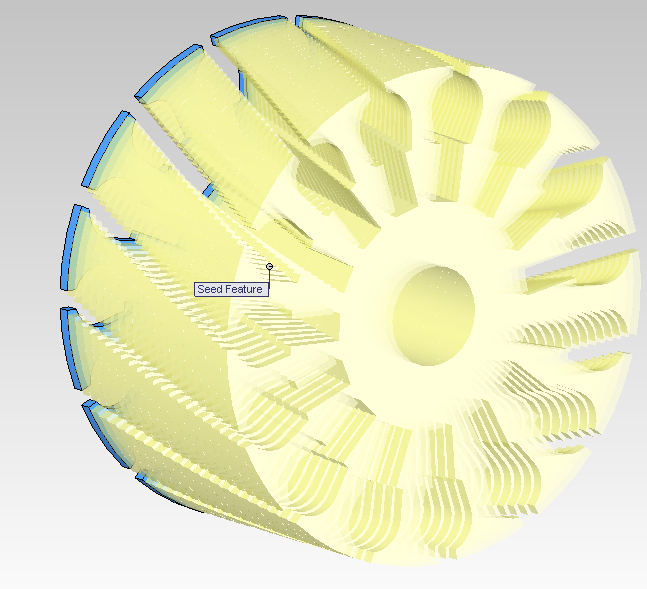

Start with a shaft with a hole in it.

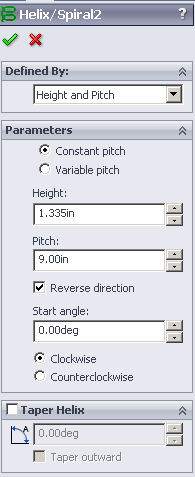

Add Helix to part controlling the pitch. You can calculate the pitch by multipling the material thickness by 360, seeing that each part moves 1 degree instance.

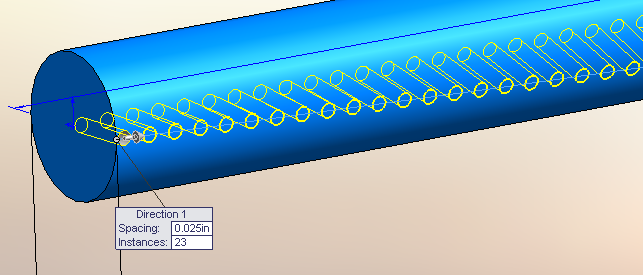

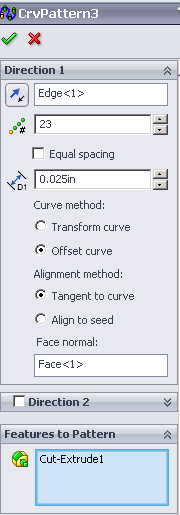

Now use the Helix to create a Curve Driven Pattern.

Now insert that part in the assembly with one shim and perform a Feature Driven Pattern. The Feature Drive Pattern will update based on the patterning part. So you only have to change the curve driven pattern in the part to update the pattern in the assembly of the shim.

Also another hint so your pattern part does not show in your BOM. Right mouse button click on the pattern part and open component properties. Check the option for Exclude from BOM.

Enjoy,

Bob McGaughey, CSWE

CATI

Blog

Blog